A University of Leeds researcher has won a national entrepreneurship prize for his work in developing a new method of counterfeit-proofing glass.

Dr Matthew Murray, a research fellow in the University’s School of Chemical and Process Engineering, will receive the 2015 Royal Academy of Engineering-ERA Foundation Entrepreneurs’ Award, one of the Academy’s most prestigious awards for entrepreneurs.

He is spearheading the commercialisation of a new laser technology that creates patterns of new material in the structure of glass that are impossible to counterfeit.

Because these patterns can carry detailed information such as where and when a product was manufactured, the technique could play a major role in tackling counterfeit goods in sectors that rely on glass containers, such as pharmaceuticals, alcohol and perfumes.

Fakes in these industries are not only responsible for massive financial losses but, in some sectors, major health risks.

Dr Murray is a member of the team behind Ultramatis Ltd., a new University of Leeds spinout established to commercialise the technology, dubbed Alpin.

The RAEng-ERA prize will be presented on the 16th of July at an annual awards ceremony. Awarded for innovation in electro-technology, the prize brings the backing of the Academy’s Enterprise Hub, including a £30,000 investment and mentoring for Dr Murray from a senior member of the Academy’s fellowship.

Dr Murray will be given intensive training in business skills over the next year, access business networks as a member of the Hub and a £10,000 personal prize.

He was one of a small group researchers selected to give 10-minute pitches about their innovations to a panel of senior engineers and business people.

“We all had to do a 10-minute presentation and then each of us was grilled by on our technology, business plan and our personal drives and ambitions. It really did feel exactly like Dragon’s Den. The fact that our technology is proven and the business case is clear made it easier for me,” Dr Murray said.

He said: “The challenge now facing us is to make the technology into a viable commercial product. This award will give us a tremendous boost and, for me personally, it will help me make the transition from researcher to entrepreneur.”

“We are determined to develop these products within the UK. All too often, we see British universities developing amazing technologies and then watch the manufacturing go abroad. We are committed to developing a company around this technology that will provide a platform for further innovation.”

The new technology uses high-powered, short-pulsed lasers to generate plasma from a target material that is then implanted into the glass.

Professor Gin Jose, who leads the research team in the University’s School of Chemical and Process Engineering that developed the technique, said: “The lasers put in tremendous amounts of energy, stripping apart atoms and electrons in the material we want to implant.

“This forms a plasma—a highly charged energetic gas—that travels at several miles a second into the glass. The resulting material is not just a new surface; it is integrated into the structure of the glass itself, creating a new material with its own properties.”

Critically for the battle against counterfeiters, the resulting materials have special optical properties.

Dr Murray said: “When we shine a laser on the material, we get a very specific light signature that cannot be mimicked with another method. The signature changes depending on what combination of materials we implant, allowing us to encode information securely in the glass.

“We can say, for instance, that a whisky was manufactured on a particular day for a particular brand and cross reference a specific barcode. This could be used to ensure the integrity of supply chains of perfume, alcohol, drugs or even crucial glass products such as aeroplane windows.”

Arnoud Jullens, Head of Enterprise at the Royal Academy of Engineering, said: “Matthew’s plasma technology will help to add another layer of protection against counterfeit products worldwide; an issue of growing importance, particularly in developing countries.

“The support offered by the Enterprise Hub’s network of business leaders will help Matthew to find the right partners and customers to take his product to the global market.”

The runners-up for the Entrepreneurs’ Award included academics from Oxford University and University College London, each of whom will be awarded £2,000 prizes.

Professor Sir Richard Brook, Chairman of the selection panel, said: “This year’s candidates showcase how far and wide electro-technology can be used to solve contemporary issues. All of the individuals involved have shown a high level of commitment and entrepreneurship and with the support of the Enterprise Hub will be able to take their ideas to the next level.”

Further information on past winners of the ERA Foundation Award and current Enterprise Hub members can be found on the Enterprise Hub website: http://www.enterprisehub.raeng.org.uk

Ultramatis Ltd. was set up in November 2014 by the University of Leeds and IP Group Plc. for commercial exploitation of the technology.

Further information

Dr Murray is available for interview. Contact the University of Leeds press office on 0113 343 4031 or email pressoffice@leeds.ac.uk

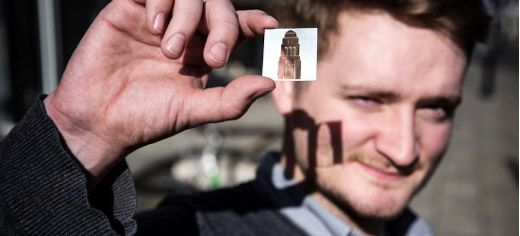

Photo: Dr Matthew Murray.

Credit: Royal Academy of Engineering Enterprise Hub.